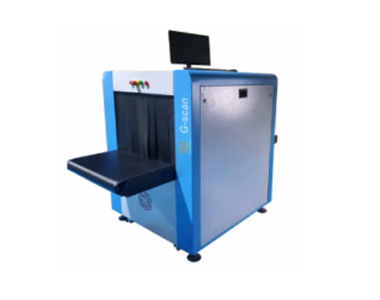

Under the guidance of Mr. Gahininath Gujar the company was established in the year 2017. M/S Gujar Industries India Private Limited is based in Pune, India. M/S Gujar Industries India Private Limited is a popular name, associated with manufacturing and supplying X Ray Baggage Scanner, Baggage Scanner Machine, Baggage X Ray Scanner, Airport Baggage X-Ray Machine, X-Ray Baggage Inspection System, X-Ray Food Inspection Systems, and Threat Detection Systems. The products manufactured by us are developed using top-quality raw materials of international repute and these products are available at reasonable prices. We manufacture these machines keeping in mind the varied requirements of today’s industry. Our baggage scanner machines are perfect to ensure the most contemporary security solutions and are a technological genius, who smartly classifies the materials scanned based on their composition.

+91-9657440677

+91-9657440677

With more than a decade of experience, we have established ourselves as a trusted importer, exporter and supplier of superior quality products. Our machines boast of highly desirable characteristics like superior construction, reliable output, unmatched performance and long-lasting service life, which make them a favorite among the clients.

Some other specifications of the X-Ray Baggage Inspection System are Image of Previous Baggage, Real-Time Image Processing and Zoom, Automatic Image Archiving, First In First Out Archiving, Manual Image Archiving, Baggage Counter, Programmable Function Keys, Date/Time Indicator, Organic Danger Alarm, Threat Image Projection, Inorganic Danger Alarm, Suspicious Bag Alarm, Operator Training Program and more.

Unlike traditional x-ray baggage scanners, our products are designed with certain features that can display different colors on the screen as defined by the atomic number of the materials scanned. This allows the machine operator to detect differences between the types of materials inside the bags such as powder, metals, plastic, liquid and more.

Threat detection equipment combines the benefits of highly efficient solid-state detectors. They are designed keeping in mind the possible threats in public infrastructures and the commercial sectors. They are suitable for a wide range of sectors, such as law enforcement, border security, post services, transport, government buildings, prisons, and large sports/entertainment events. Also, our threat detection devices can be used at airports, shopping malls, railway stations, pilgrimages. The systems contribute to the protection of public places and improve the detection and prevention of biological, chemical, radiological, explosive and nuclear incidents.

Our x-ray baggage scanners, airport baggage x-ray machine or X Ray Food Inspection Systems features convenient operation, simple installation and easy maintenance. They are ideal to inspect small and large baggage with the feature of 2D or 3D imaging of suitcase. Get in touch if you are searching for leading manufacturers and suppliers of threat detection systems. We manufacture our products using advanced technology as per the national and international quality standards.

See, How our Advance X-Ray Baggage Scanner Machine (Inspection System) works with a Powerful Threat Detection System to Find the Suspected Materials, which is helpful at Railway Stations, Metro Stations, Bus Stations, Public VIP Events, Hotels, Malls, Museum, Holy Places (Temple), Multiplex Cinema Hall, IT Offices, Corporate Office, Logistics & Warehouses, Exhibition Centers and Stadiums.

Gujar Industries has been a proud and trusted supplier to government agencies and private security operations around the world. Our success has been built on the following: –